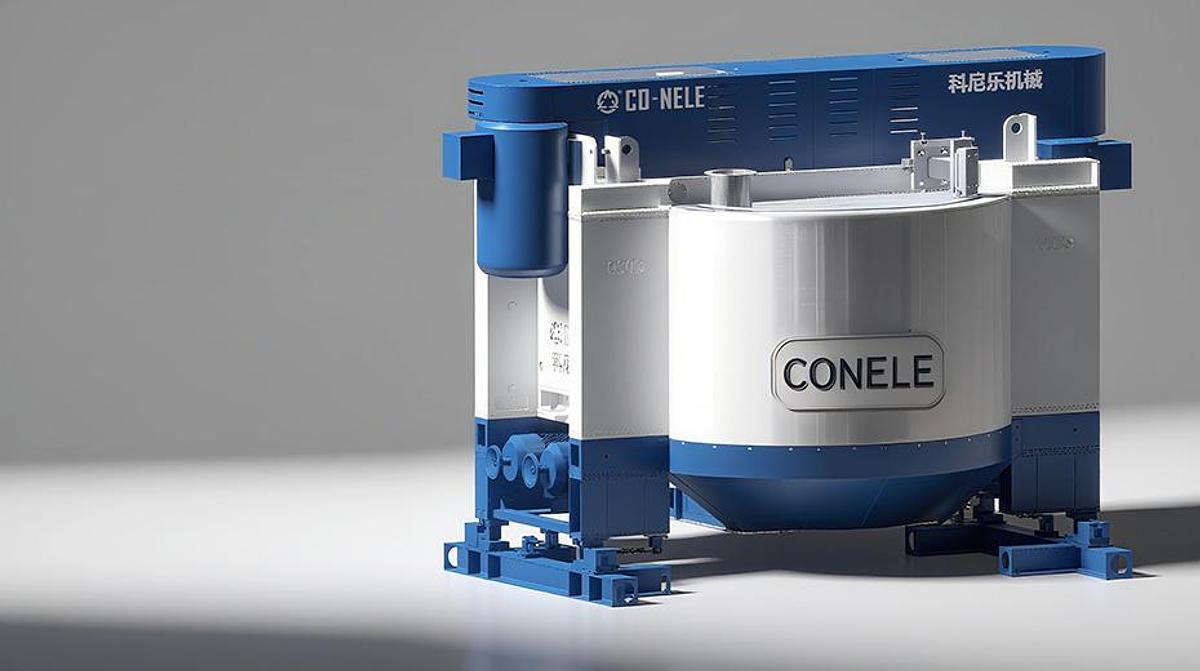

CR / CRV Intensive Mixer

CR / CRV Intensive Mixer

Description

Product Introduction

CR/ CD Intensive mixer Unique mixing principle of the CR series Intensive mixers ensure constant, reproducible product quality with minimal mixing times for batch operations. While the mixing device is rotating at high speed, the drum is driven by the reducer for rotation, the mixing drum is tilted at an angle to improve the mixing. It is inclined at a certain angle to realise a three-dimensional stirring mode, so that the material is turned more consistently, and the mixing is more uniform. The mixing direction is divided into forward and reverse. CEL series Intensive mixer are laboratory mixers with a size range from 1 to 10 liters are available. CR series Intensive mixer sizes from 5 to 50 liters are also available. Flexible high-performance mixing system for challenging tasks in the fields of research, development, and small-scale production. The multi-functional mixing system can be used for many different applications, e.g. for mixing, granulating, coating, kneading, dispersing, dissolving, defibering and many more.

Lead to the future mixing: Intensive mixer can guarantee the following three points

The mixer and the rotor move together. At the same time, the mixing device can cut, blend, and mix the material in a complex mixing cycle, giving a very good mixing effect. In the turning mixing pan, the material is pushed to the scraper. Then turned over, that promotes the mixing up and down. The mixing blade can strip the material at the bottom and side of the mixer. Can shorten the discharge time.

Mechanical Features

1. Gearing System: It can be selected for different demands of power, revolutions, direction of rotation and energy transfer mode according to the task. Friction gear or ring gear driver mixing drum. The motor drives the gearbox by vee belt Then the gearbox drives the mixing device.

2. Mixing device: While the material is rotating with the mixing drum, a force is generated between the mixing drum and the mixing device that is rotating the opposite direction in the centrifugal position. The wolfram carbide compounded liner ensures a durable quality and an easy maintaining. The shape and quantity of the mixing blade depends on the material to mix. The blades are also easy to replace.

The advantages: The mixer mixes without demixing effects; 100 % material circulation during one rotation of the mixing pan Optimal mixing effects are achieved with only one mixing tool. Various consistencies can be processed in the mixer. High mixing quality is reached even with short processing times. Industrial scale-up of test results are possible.

3 Discharging device: Special sealing device is applied to the discharging gate to prevent from leaking.

4.Maintaining Door: On the consideration of personnel safety and market demand, we adopt reliable high-sensitive security switches to be equipped on the maintaining door. There is an observing port on the maintaining door, observing is possible without cutting off the power.

Wear-resistance liner/blade

Because the mixed material is abrasive to the structural parts it comes into contact with, the choice of materials for these structural parts must be targeted, and CO-NELE provides a reliable choice for wear resistant materials. High-quality steel as structural material Vulcanized rubber lining and specialty plastics PTFE, Viton, and other sealing materials Carbide coating Carbide cladding High-grade alloy steel non-ferrous metals Ceramic material.

Applications

Ceramics: CO-NELE Intensive mixer can be used to mix, homogenize , granulate, plasticize, suspend, cool or heat as well for reactions – and all this in a single machine. Molding compounds, molecular strainers, proppants, varistor compounds, dental compounds, cutting ceramics, grinding agents, oxide ceramics, non-oxide ceramics, composite materials, silicate technical ceramic grinding balls, ferrites, etc.

Refractory: CO-NELE has been the leading supplier of cutting-edge technologies for the preparation of refractory compounds. Shaped, Unshaped products, Prefabricated parts, Mixtures and granules for oxide and nonoxide ceramic material, mixtures for ceramic fiber materials.

Concrete: Porous media of bricks, expanded clay, perlite, etc., refractory ceramsite, clay ceramsite, shale ceramsite, ceramsite filter material, ceramsite brick, ceramsite concrete, etc.

Glass: Glass powder, carbon, lead glass mixtures, waste glass slag etc.

Metallurgy: When processing raw materials to produce green pellets, ultrafine ores are mixed with binding agents (e.g., bentonite) and aggregates (e.g., limestone or dolomite). Zinc and lead ore, aluminum oxide, silicon carbide, iron ore, etc.

Chemistry: Lime hydrate, dolomite, phosphate fertilizer, peat fertilizer, mineral compounds, sugar beet seeds, etc.

Environmental technology: Fly ash, slag, dust, sludge, cement filter dust, fly ash, slurries, dusts, lead oxide, Phosphates gypsum etc. Lithium battery material, flux, friction material, bentonite bonded sand.

Specifications

| Condition | New |

| Stock Number | CR / CRV Intensive Mixer |